The delicate craft of jewelry making is an art form that has been cherished for centuries. It is a blend of creativity, precision, and technical skill, where each piece tells a unique story. Among the many techniques used by jewelers, soldering stands out as a fundamental process that transforms raw materials into intricate works of art. The jewellers soldering iron is the heart of this process, a tool that, when wielded with care and skill, can create seamless connections and repairs, adding both strength and beauty to a piece of jewelry.

In this article, we will explore the world of jewellers soldering irons, delving into their types, uses, and the essential considerations for selecting the right one for your jewelry-making needs. We will also take a closer look at the ATETOOL AE561D soldering iron, one of the top options available in the market today. Whether you are a seasoned professional or a budding artisan, understanding the nuances of soldering tools is crucial to elevate your craft to the next level.

A jewellers soldering iron is a specialized tool designed for the precise and delicate work required in jewelry making. Unlike traditional soldering irons, these tools are crafted to handle the small and intricate components often used in jewelry. They are characterized by their fine tips, which allow for detailed work, and their temperature control, ensuring that the heat is evenly distributed without damaging the delicate materials.

Temperature Control: The ability to regulate the temperature is crucial for different types of soldering jobs. Some materials require lower temperatures to avoid damage.

Fine Tips: The tips of a jewellers soldering iron come in various shapes and sizes to accommodate the detailed work often necessary in jewelry making.

Ergonomic Design: A comfortable grip and lightweight design are essential for prolonged use, reducing fatigue and ensuring precision.

Portability: Many jewellers prefer portable soldering irons for their convenience, especially when working on location or in small spaces.

Safety Features: Given the high temperatures involved, safety features such as heat-resistant handles and automatic shut-off mechanisms are vital.

Durability: A high-quality soldering iron will stand the test of time, with materials and construction that resist wear and maintain performance.

As we proceed, we will explore these features in greater detail, helping you understand what to look for in a soldering tool for jewelry and how to choose the one that best suits your specific needs and preferences.

The world of soldering tools for jewelry is vast and varied, offering a multitude of options tailored to different needs and preferences. Each type of soldering tool has its unique characteristics, advantages, and ideal applications within the realm of jewelry making.

These portable and easy-to-use tools are powered by butane gas, making them perfect for on-the-go soldering. They offer a quick heat-up time and adjustable flame, providing versatility for various soldering tasks.

Electric soldering irons are known for their consistent temperature control, which is essential for precision soldering. They are typically more stable and offer better temperature regulation than butane torches.

Cordless soldering pens provide the convenience of portability without the need for a gas source. They are battery-operated and often come with interchangeable tips for a variety of soldering tasks.

For the serious jeweler, professional soldering stations offer advanced features such as digital temperature control, heavy-duty construction, and a variety of attachments for specialized work.

When comparing different soldering tools for jewelry, consider the following factors:

Heat Source: Butane torches offer portability, while electric irons provide consistent heat.

Temperature Control: Adjustable temperature is crucial for working with different types of metals.

Tip Variety: A range of tips allows for greater versatility in your soldering projects.

Ease of Use: Some tools are more user-friendly, especially for beginners.

Price: The cost of the tool should align with your budget and the quality you require.

Selecting the right soldering iron for your jewelry-making projects is a critical decision that can impact the quality of your work and the efficiency of your process. Here are some key factors to consider when choosing a soldering iron:

Frequency of Use: If you solder regularly, invest in a high-quality, durable tool.

Type of Jewelry: The complexity and size of the jewelry you create can influence the type of soldering iron you need.

Cost vs. Quality: Higher-priced tools often offer better performance and durability, but there are affordable options that still provide good results.

Adjustable Temperature: Ensure the soldering iron can handle a range of temperatures for different soldering tasks.

Interchangeable Tips: Different projects may require different tip sizes and shapes.

Grip: A comfortable grip can reduce fatigue during long soldering sessions.

Weight: A lighter tool can be easier to handle, especially for detailed work.

Heat Resistance: The tool and its components should be able to withstand high temperatures.

Safety Mechanisms: Features like automatic shut-off can prevent accidents.

By taking these factors into account, you can make an informed decision and choose a soldering iron that will serve you well in your jewelry-making endeavors. In the next section, we will take a closer look at the ATETOOL AE561D soldering iron, exploring its features and why it might be the right choice for you.

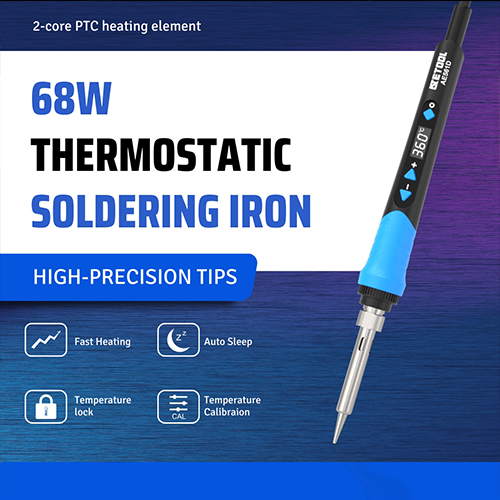

ATETOOL AE561D soldering iron is a standout option in the market, favored by many for its combination of performance, versatility, and reliability. This section will provide an in-depth look at what makes this soldering iron a popular choice among jewelers.

Digital Temperature Control: Allows for precise temperature settings, crucial for working with various metals without overheating.

Quick Heat-Up Time: The ATETOOL AE561D heats up rapidly, reducing wait time and increasing productivity.

Durable Construction: Made with high-quality materials to ensure longevity, even with frequent use.

Safety Features: Equipped with safety features such as a stand for resting the hot iron and an automatic shut-off function.

Accessories: Often comes with a range of interchangeable tips to suit different soldering tasks.

Precision: The fine tips allow for detailed work on intricate jewelry pieces.

Consistency: Maintains a stable temperature, preventing overheating and ensuring even soldering.

Ease of Use: User-friendly design with features that cater to both beginners and professionals.

Value for Money: Offers a balance of quality and affordability, making it accessible to a wide range of jewelers.

Safety is paramount when working with soldering tools, especially in a craft that requires such precision and attention to detail. This section outlines essential safety precautions and best practices to follow when using a jewellers soldering iron.

Ventilation: Always work in a well-ventilated area to avoid inhaling fumes from the solder and flux.

Personal Protective Equipment (PPE): Wear heat-resistant gloves, safety glasses, and a fire-resistant apron.

Flame Control: When using a torch, keep flammable materials away and be mindful of open flames.

Electrical Safety: For electric soldering irons, ensure the iron is not damaged and the power source is secure.

Proper Storage: Store your soldering iron in a safe place when not in use, especially if it has been recently used and is still hot.

Cleaning: Regularly clean the tip of your soldering iron to maintain its performance and prolong its life.

Temperature Management: Do not set your soldering iron to a higher temperature than necessary for the task at hand.

Work Area Organization: Keep your workspace clean and organized to prevent accidents and improve workflow.

By adhering to these safety precautions and best practices, you can ensure a safe and productive soldering experience, allowing you to focus on creating beautiful and durable jewelry pieces.

While soldering irons are essential tools for jewelry makers, they can sometimes present challenges. This section will guide you through some common issues and offer solutions to help you maintain the efficiency and effectiveness of your soldering work.

Tipped Over: If your soldering iron tips over, immediately turn it off and let it cool. Consider using a stable stand to prevent accidents.

Clogged Tips: Build-up on the tip can affect heat transfer. Regular cleaning with a damp sponge or brass wire brush can help.

Inconsistent Temperature: If your soldering iron isn't maintaining a steady temperature, it may need calibration or a new heating element.

Poor Soldering Joints: Ensure the metal is clean and the soldering temperature is correct. Using the right type of solder for the metal you're working with is also crucial.

Regular Maintenance: Clean and inspect your soldering iron after each use to catch any potential issues early.

Proper Storage: Store your soldering iron in a cool, dry place to prevent damage and prolong its lifespan.

Training: If you're new to soldering, practice on scrap materials to get a feel for the tool and technique before working on valuable pieces.

As technology advances, so does the equipment used in jewelry making. The future of soldering tools is likely to bring about improvements in precision, safety, and user-friendliness.

Smart Soldering Irons: Future soldering irons may incorporate sensors and microprocessors to provide real-time feedback on temperature and usage.

Wireless Technology: The development of wireless charging for cordless soldering tools could increase mobility and convenience.

Eco-Friendly Solutions: There may be a shift towards more environmentally friendly materials and processes in soldering tools.

Customization: Users may be able to customize their soldering irons with different attachments and settings tailored to their specific needs.

Integration with Other Tools: Soldering irons could become part of a larger ecosystem of jewelry-making tools, with seamless integration for workflow efficiency.

In conclusion, the jewellers soldering iron is an indispensable tool in the field of jewelry making. From understanding the different types of soldering tools to choosing the right one for your needs, and from ensuring safety to staying informed about technological advancements, this article has provided a comprehensive guide to help you make the most of your soldering experience.

The ATETOOL AE561D soldering iron, with its array of features and benefits, stands as a testament to the quality and innovation available in today's market. By following best practices and safety precautions, and by keeping an eye on the future of soldering technology, you can continue to create beautiful and enduring pieces of jewelry.

As you continue your journey in the art of jewelry making, remember that the right tools, coupled with skill and creativity, can unlock a world of possibilities. Happy soldering!

Contact: Karen

Phone: (0086) 755 2340 8754 ext. 807

E-mail: atetool@atetool.com.cn

Add: 5F, 1-2# Building, Tongfuyu Industrial Zone, Aiqun Rd, Shiyan Subdistrict, Bao'an, Shenzhen, 518108, China