Soldering can be a delicate task, whether you're a DIY enthusiast or a professional. The quality of your solder joints can significantly impact the functionality and durability of your electronic projects. This is where a temperature controlled soldering iron becomes your best ally. These sophisticated tools allow you to set and maintain precise temperatures, ensuring consistency and protecting your components from overheating. In this guide, we'll delve into everything you need to know about temperature controlled soldering irons and why they are a game-changer in the world of soldering.

A temperature controlled soldering iron is a tool that allows you to set a specific temperature for the iron's tip. Unlike traditional soldering irons that simply heat up to a single, uncontrolled temperature, these advanced versions come equipped with heating elements and temperature sensors. This technology ensures that the tip maintains a consistent temperature, which is crucial for creating reliable and high-quality solder joints.

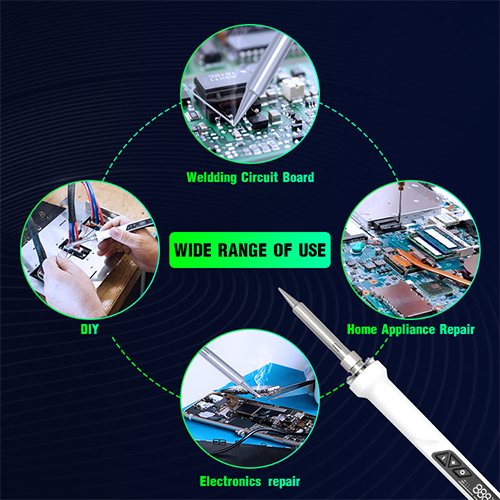

Many DIY enthusiasts and professional technicians alike prefer temperature controlled soldering irons for their superior precision and versatility. These irons enable users to tackle a range of tasks, from delicate circuit board repairs to heavy-duty soldering jobs, with equal ease. The ability to control the temperature means you can work with different types of solder and components without the risk of damaging sensitive parts. For professionals, this translates to increased efficiency and reduced errors, while hobbyists enjoy the enhanced control and improved results.

Temperature controlled soldering irons might seem magical, but they operate on straightforward and highly effective principles. Grasping how these devices work can help you make an informed decision when selecting one for your needs.

At the core of a temperature controlled soldering iron is its heating element, often made from materials like nichrome or ceramic. This element heats up when electrical current passes through it. Integrated with the heating element is a temperature sensor, typically a thermocouple or thermistor. The sensor continuously monitors the tip's temperature and communicates with the soldering iron's control unit. When the sensor detects a deviation from the set temperature, it signals the control unit to adjust the current flowing to the heating element, thus maintaining a stable temperature.

Temperature controlled soldering irons come with either analog or digital interfaces. Analog models usually feature a dial that you turn to set the temperature. They are often simpler and more intuitive for quick adjustments but lack precise temperature control. Digital soldering irons, on the other hand, come with digital displays and buttons, offering precise temperature settings and real-time feedback. They may also include additional features such as temperature presets, sleep modes, and calibration options. Choosing between analog and digital depends on your specific needs and preferences, with digital generally providing more control and functionality.

Temperature controlled soldering irons offer numerous benefits that make them indispensable for both hobbyists and professionals. Here we'll discuss two major advantages.

One of the primary benefits of a temperature controlled soldering iron is its precision. By allowing you to set a specific temperature, these irons ensure that your soldering tip stays at that temperature consistently. This level of control is crucial for achieving high-quality solder joints. Consistent temperature means you can deliver the right amount of heat needed to melt the solder properly, forming strong, reliable connections. Whether you're working on delicate electronic components or larger metal pieces, this precision helps prevent cold solder joints and ensures durability and functionality.

The importance of temperature control becomes even more evident when considering the protection of your components. Different materials require different soldering temperatures. For instance, some delicate electronic components can be easily damaged by excessive heat. A temperature controlled soldering iron allows you to choose the optimal temperature, reducing the risk of thermal damage. Moreover, it helps to avoid issues like overheating or burning of sensitive parts, thereby preserving the integrity of your projects. By using the right temperature, you also prevent oxidation of the soldering iron tip, which can extend the lifespan of both your tool and your components.

When shopping for a temperature controlled soldering iron, you’ll find options catering to different levels of expertise and project requirements. Here, we categorize the types based on their intended users.

For those new to soldering or working with basic projects, entry-level temperature controlled soldering irons are a perfect choice. These models are typically more affordable yet offer essential features for effective soldering. Basic models might include analog controls with dials for temperature adjustment, but they still provide the crucial benefit of maintaining a set temperature. These irons are lightweight, user-friendly, and functional, making them ideal for beginners looking to get started without a significant investment.

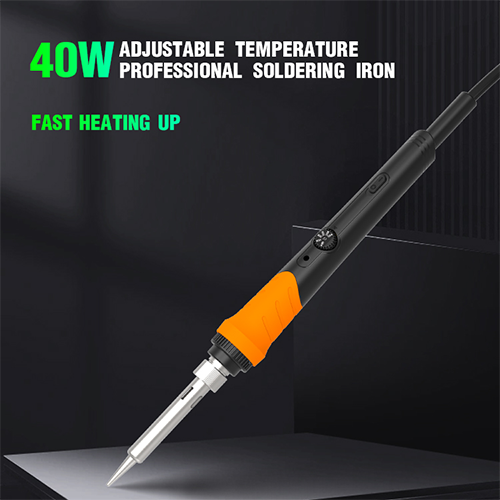

For seasoned professionals and serious hobbyists, professional-grade temperature controlled soldering irons provide advanced features and higher performance. These units often come with digital displays for precise temperature settings, memory presets for different tasks, and rapid heating capabilities. They may also offer enhanced ergonomic designs for comfortable long-term use and additional accessories like various interchangeable tips for specialized work. With robust construction and higher wattage, they can handle more demanding projects, making them a valuable tool for anyone needing reliability and consistency in their soldering endeavors.

When selecting a temperature-controlled soldering iron, look for models with digital displays and controls. These provide a user-friendly interface, allowing you to easily view the current temperature and make precise adjustments as needed. Digital controls often include features like temperature presets, sleep modes, and lock functions, making the soldering process more efficient and convenient.

The best temperature-controlled soldering irons offer a wide range of temperature adjustability, catering to the diverse needs of different projects and materials. Look for models that can reach temperatures ranging from 200°C (392°F) to 450°C (842°F) or higher, depending on your requirements. This flexibility ensures you can tackle a variety of tasks, from delicate electronics to heavy-duty metalwork, with the appropriate temperature setting.

Proper temperature selection is crucial for achieving high-quality solder joints. As a general guideline, start with lower temperatures around 300°C (572°F) for delicate electronic components and gradually increase the temperature for thicker or more conductive materials. For example, solder joints on circuit boards may require 320°C (608°F), while soldering copper pipes may need 370°C (698°F) or higher. Experiment with different temperatures to find the sweet spot for your specific project and materials.

To ensure the longevity and optimal performance of your temperature-controlled soldering iron, follow these maintenance tips:

Clean the tip regularly by wiping it with a damp sponge or cloth to remove any residue or oxidation.

Tin the tip before and after each use to protect it from corrosion and maintain good heat transfer.

Store the iron in a stand or holder when not in use to prevent damage to the tip.

Calibrate the temperature sensor periodically to ensure accurate temperature readings.

Replace the tip when it becomes severely worn or damaged to maintain consistent heat delivery.

Follow the manufacturer's instructions for any additional maintenance or care recommendations.

For those just starting out or working with a limited budget, there are several affordable yet reliable temperature controlled soldering irons to consider. The AE730D USB soldering iron is a cost-effective option that provides essential temperature control features. With a temperature range of 230°C to 450°C (446°F to 842°F) and a digital display, it offers the precision needed for basic electronics projects. Its compact and lightweight design makes it easy to handle, while the USB connectivity allows for convenient power supply.

Another notable mention is the AE541 Basic Soldering Iron. Although slightly less advanced than the AE730D, it offers a temperature range of 200°C to 480°C (392°F to 896°F). It features an analog dial for temperature control, making it a straightforward choice for beginners. Its comfortable grip and quick heat-up time make it a reliable tool for simple soldering tasks.

Professionals and serious hobbyists seeking top-of-the-line performance should look into high-end temperature controlled soldering irons. The AE680D digital soldering iron is a prime example of a professional-grade tool. With a temperature range of 100°C to 500°C (212°F to 936°F), this iron provides the versatility to handle a wide variety of soldering tasks. Its digital display and intuitive controls make it easy to set and maintain the precise temperature required. Additionally, the AE680D features a sleep mode, temperature lock, and calibration options, ensuring consistent results and prolonged tip life. For those willing to invest in a premium soldering tool, the AE680D delivers exceptional quality and performance.

Another top contender in the professional category is the AE690D Precision Soldering Iron. This iron offers an impressive temperature range of 200°C to 500°C (392°F to 932°F), making it suitable for even the most demanding projects. It includes advanced features such as temperature locking, °C and °F temperature unit switch, and an automatic standby mode. The AE690D’s high heat stability and quick recovery time make it an invaluable tool for intricate soldering work and prolonged use.

Investing in a temperature controlled soldering iron can significantly enhance your soldering experience. These tools provide the precision and consistency necessary for high-quality work, protecting your components from thermal damage. Whether you're a beginner looking to improve your skills or a professional needing reliable performance, a temperature controlled soldering iron is a worthy investment. With features tailored to various skill levels and project requirements, they ensure you achieve perfect solder joints every time.

With the knowledge and tools outlined in this guide, you're well on your way to mastering the art of soldering. Temperature controlled soldering irons offer the flexibility and control needed to tackle a wide range of projects, from simple repairs to complex electronic assemblies. Don’t wait—equip yourself with the right soldering iron and start creating flawless connections today!

Contact: Karen

Phone: (0086) 755 2340 8754 ext. 807

E-mail: atetool@atetool.com.cn

Add: 5F, 1-2# Building, Tongfuyu Industrial Zone, Aiqun Rd, Shiyan Subdistrict, Bao'an, Shenzhen, 518108, China