Stained glass artistry combines precision, creativity, and craftsmanship. Central to this intricate art form is the process of soldering, which ensures the durability and aesthetic appeal of stained glass pieces. Whether you're a beginner exploring this timeless craft or a seasoned artisan seeking to refine your techniques, selecting the right soldering iron is crucial. Let's delve into everything you need to know about choosing the best tools for soldering stained glass.

Soldering plays a pivotal role in the creation and restoration of stained glass masterpieces. It involves joining pieces of colored glass together using molten metal alloy (solder) to form solid, decorative seams. Beyond functionality, soldering enhances the visual appeal of stained glass by providing smooth, continuous lines that highlight intricate designs. Choosing the right soldering iron ensures precision and control, crucial for achieving clean and professional-looking solder seams.

When it comes to soldering for stained glass, the type of soldering iron or station you use significantly impacts your work's quality and efficiency. Traditional soldering irons with fixed temperatures may suffice for basic projects, but adjustable temperature soldering stations offer greater flexibility and control. These stations allow you to fine-tune the heat according to the thickness and type of glass, ensuring consistent solder flow and minimizing the risk of overheating delicate pieces.

Selecting the appropriate soldering tools involves considering several key factors tailored to stained glass work. Wattage is a critical consideration; higher wattage irons heat up faster and maintain consistent temperatures, ideal for working with thicker glass pieces. Ergonomic features such as lightweight handles and heat-resistant grips reduce fatigue during extended soldering sessions, promoting comfort and precision.

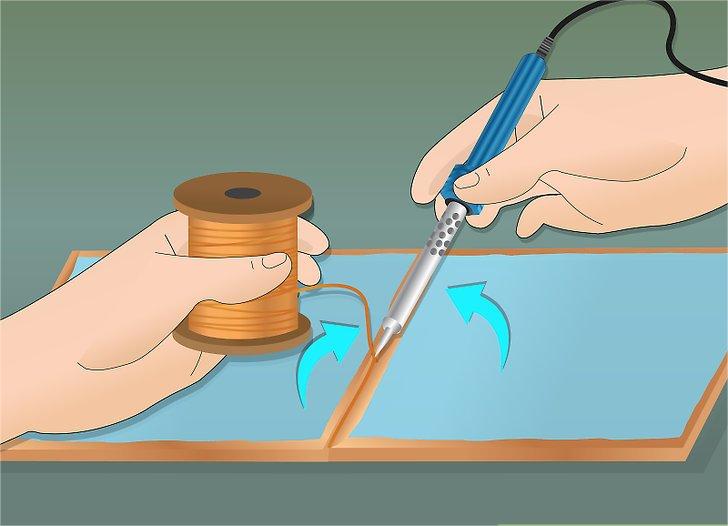

Achieving impeccable solder joints requires adherence to best practices. Begin by thoroughly cleaning and fluxing the glass edges to ensure proper adhesion of the solder. Maintain a steady hand and a consistent soldering technique to avoid excessive solder buildup or gaps in the seams. Regularly clean the soldering tip with a damp sponge to prevent oxidation and maintain optimal heat transfer, crucial for achieving smooth and uniform solder lines.

For beginners in stained glass, investing in a comprehensive soldering kit is advisable. These kits typically include essential accessories such as flux, solder wire, and a soldering stand, providing everything needed to start soldering immediately. Additional accessories like heat-resistant gloves and safety glasses protect against burns and eye strain, ensuring a safe and comfortable soldering experience.

Chinese manufacturers offer a compelling choice for sourcing soldering irons, combining affordability with quality craftsmanship. Many renowned brands provide a wide range of soldering tools tailored to different skill levels and applications, including stained glass work. With rigorous quality control measures and competitive pricing, Chinese soldering irons offer excellent value for money without compromising on performance or durability.

Contact: Karen

Phone: (0086) 755 2340 8754 ext. 807

E-mail: atetool@atetool.com.cn

Add: 5F, 1-2# Building, Tongfuyu Industrial Zone, Aiqun Rd, Shiyan Subdistrict, Bao'an, Shenzhen, 518108, China