Soldering is a fundamental technique in the world of electronics, craftsmanship, and DIY projects. The ability to precisely control the temperature of your soldering iron is crucial for achieving high-quality, consistent results. Temperature-controlled soldering irons have become a game-changer, allowing users to fine-tune the heat to match the specific needs of different materials and applications.

Temperature-controlled soldering irons are designed to maintain a consistent, user-defined temperature throughout the soldering process. This is achieved through the use of a built-in temperature sensor and a control mechanism that regulates the power supply to the heating element. By providing precise temperature control, these irons ensure that the solder melts at the optimal temperature, leading to stronger, more reliable connections.

1. Precise Temperature Adjustment

Temperature-controlled soldering irons allow you to adjust the temperature in small increments, typically ranging from 200°C to 450°C (392°F to 842°F). This level of precision is essential for working with a wide variety of materials, from delicate electronic components to thick, heavy-duty joints.

2. Consistent Heat Output

The built-in temperature sensor and control mechanism maintain a steady heat output, preventing fluctuations that can lead to inconsistent solder joints or damage to sensitive components.

3. Faster Heating and Cooling

Many temperature-controlled soldering irons heat up and cool down quickly, reducing the time needed for each soldering task and improving overall efficiency.

4. Improved Safety

The precise temperature control and stable heat output of these irons reduce the risk of accidental burns or fires, making them a safer choice for both professionals and hobbyists.

When selecting a temperature-controlled soldering iron, there are several factors to consider:

1. Power Output

The power output of the soldering iron should match the type of work you'll be doing. Higher-wattage irons (40-80W) are better suited for larger, heavier-duty soldering tasks, while lower-wattage models (20-40W) are more appropriate for delicate electronics work.

2. Tip Size and Shape

The size and shape of the soldering tip can significantly impact the precision and control of your work. Choose a tip that is appropriate for the specific project or component you'll be soldering.

3. Ergonomics and Comfort

The overall design and weight of the soldering iron should provide a comfortable, balanced feel in your hand, reducing fatigue during extended use.

4. Additional Features

Some temperature-controlled soldering irons offer additional features, such as digital temperature displays, auto stanby&sleep, temperature locking, screen brightness adjustable, calibration, ℃/℉ conversion, language version, or interchangeable tips, which can further enhance the user experience.

Mastering the art of temperature-controlled soldering requires a combination of technical knowledge and hands-on experience. Here are some key techniques to help you achieve professional-grade results:

1. Preheat the Workpiece

Preheating the area you'll be soldering helps the solder flow more easily and creates a stronger, more reliable connection.

2. Use the Correct Solder Temperature

Refer to the manufacturer's recommendations or industry standards to determine the optimal temperature for your specific solder and application.

3. Maintain Proper Tip Tinning

Regularly cleaning and tinning the soldering tip helps ensure efficient heat transfer and prevents oxidation, which can degrade the tip's performance.

4. Practice Proper Soldering Technique

Focus on techniques like heat application, solder application, and joint formation to develop a consistent, high-quality soldering process.

5. Experiment and Refine

Continuously experiment with different temperature settings, tip sizes, and techniques to find the optimal approach for your specific projects and needs.

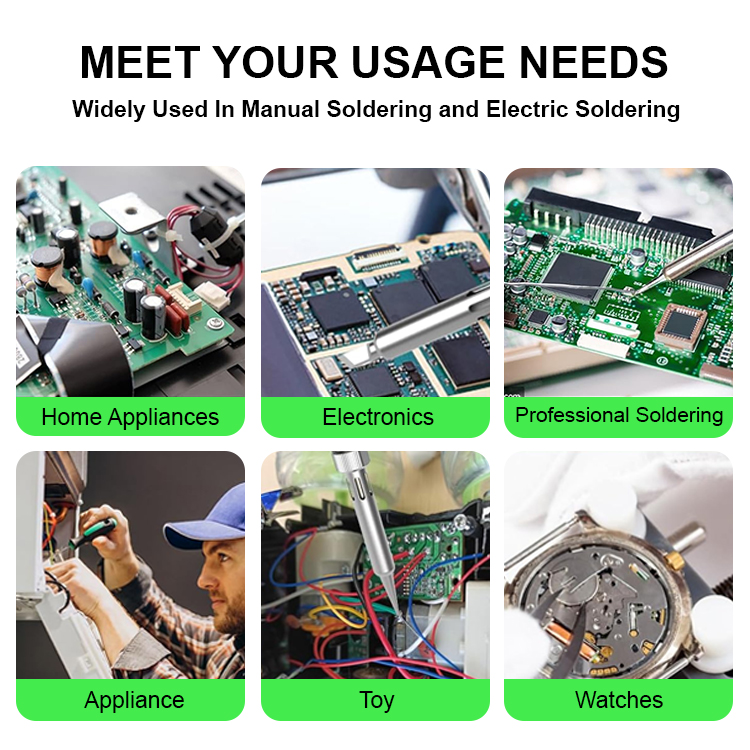

Temperature-controlled soldering irons have a wide range of applications across diverse industries, including:

Electronics and Repair

Precise temperature control is essential for working with delicate electronic components, printed circuit boards, and other sensitive electronics.

Crafts and Hobbies

Artisans, jewelry makers, and DIY enthusiasts use temperature-controlled irons for a variety of tasks, such as working with metal, glass, or even wax.

Manufacturing and Industrial

Temperature-controlled soldering is crucial in manufacturing processes, where consistent, high-quality solder joints are required for durability and reliability.

Education and Training

Temperature-controlled soldering irons are invaluable tools in STEM education, teaching students the fundamentals of electronics and soldering.

Automotive and Aviation

These industries rely on temperature-controlled soldering for a range of applications, from wiring harness repair to avionics maintenance.

Construction and Plumbing

Plumbers, electricians, and HVAC technicians use temperature-controlled soldering irons for tasks like pipe and conduit work.

Proper care and maintenance are essential for ensuring the longevity and optimal performance of your temperature-controlled soldering iron. Here are some best practices:

1. Clean the Soldering Tip Regularly

Use a damp sponge or a brass wire tip cleaner to remove any built-up solder or oxidation from the tip, ensuring efficient heat transfer.

2. Calibrate the Temperature Regularly

Periodically check the accuracy of the temperature reading and make any necessary adjustments to ensure consistent performance.

3. Store the Iron Properly

When not in use, store the soldering iron in a safe, upright position to prevent damage to the tip and cord.

4. Replace Worn or Damaged Tips

Over time, the soldering tip will wear down and require replacement. Monitor the tip's condition and replace it when necessary for optimal results.

5. Follow Safety Protocols

Always unplug the soldering iron when not in use, and be mindful of the hot tip to prevent burns or accidental fires.

Temperature-controlled soldering irons are invaluable tools that can elevate your soldering expertise and unlock a world of possibilities. By mastering the art of temperature control, you can achieve consistent, high-quality results across a wide range of applications, from delicate electronics to heavy-duty industrial projects. Whether you're a seasoned professional or a passionate DIY enthusiast, investing in a temperature-controlled soldering iron is a smart decision that will pay dividends in the quality of your work and the satisfaction of your creations.

Contact: Mr. Li

Phone: (0086) 138 24254 321

E-mail: atetool@atetool.com.cn

Add: 5F, 1-2# Building, Tongfuyu Industrial Zone, Aiqun Rd, Shiyan Subdistrict, Bao'an, Shenzhen, 518108, China